How to Select the Right Medical-Grade Lithium-ion Battery for Your Device: A Comprehensive Guide

In the rapidly evolving landscape of medical technology, the choice of a power source is not merely a technical specification—it is a critical determinant of device reliability, patient safety, and operational success. With the global medical device battery market projected for significant growth, driven by portable diagnostics, robotic surgery systems, and remote patient monitoring, selecting the correct medical battery is paramount. This guide, presented by HCC (Shenzhen Topway Technology Co., Ltd.), a pioneer in medical-grade power solutions, will walk you through the essential steps and considerations.

Why This Guide Matters

An unsuitable lithium ion battery can lead to device failure, safety hazards, and costly recalls. This guide empowers engineers, procurement managers, and product developers to make informed decisions, ensuring their medical devices are powered by safe, reliable, and high-performance battery pack solutions.

Step 1: Define Your Application and Key Requirements

The first step is a thorough analysis of your device's operational profile. This goes beyond simple voltage and capacity needs.

- Device Type & Criticality: Is it a life-sustaining device like a ventilator, a robotic surgery battery for precision tools, or a portable diagnostic monitor? The required reliability level varies drastically.

- Energy Density & Runtime: Calculate the peak and average power consumption. For compact, wearable devices, a high-energy-density 18650 battery or 21700 battery might be ideal. For longer runtime in stationary monitors, a high-capacity lifepo4 battery offers stability.

- Physical Constraints: Define the available space (dimensions of 14500 battery, 18500 battery, or custom shapes) and weight limits. HCC specializes in designing compact, high-performance packs for space-constrained medical applications.

- Environmental Conditions: Will the battery be exposed to sterilization cycles, temperature fluctuations, or humidity? Medical-grade batteries must withstand these stresses.

HCC provides tailored medical battery solutions for various critical applications.

Step 2: Choose the Right Lithium-ion Chemistry

Not all rechargeable lithium ion battery chemistries are equal. Your choice impacts safety, cycle life, and performance.

| Chemistry | Key Features | Best For Medical Applications Like... |

|---|---|---|

| Lithium Cobalt Oxide (LCO) | High energy density, common in 18650 rechargeable battery cells. | Portable monitors, handheld scanners where size is critical. |

| Lithium Iron Phosphate (LiFePO4) | Excellent safety, long cycle life, stable 12v battery systems. | Infusion pumps, hospital bedside equipment, where safety is paramount. |

| Lithium Polymer (LiPo) | Flexible form factors, lightweight, used in custom battery pack designs. | Wearable health patches, compact surgical tools, curved device housings. |

HCC's engineering team can advise on the optimal chemistry, whether it's a standard lifepo4 battery or a custom lipo battery solution, balancing performance with stringent medical safety requirements.

Step 3: Prioritize Safety and Certification Compliance

This is non-negotiable for medical devices. Your medical battery supplier must demonstrate rigorous compliance.

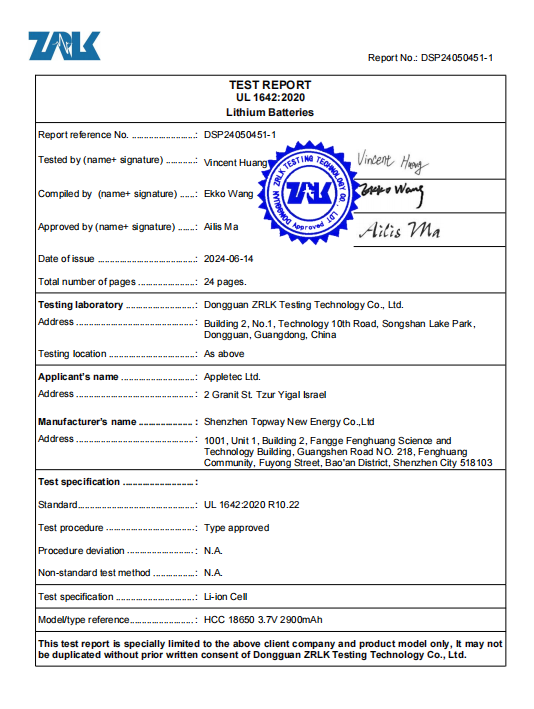

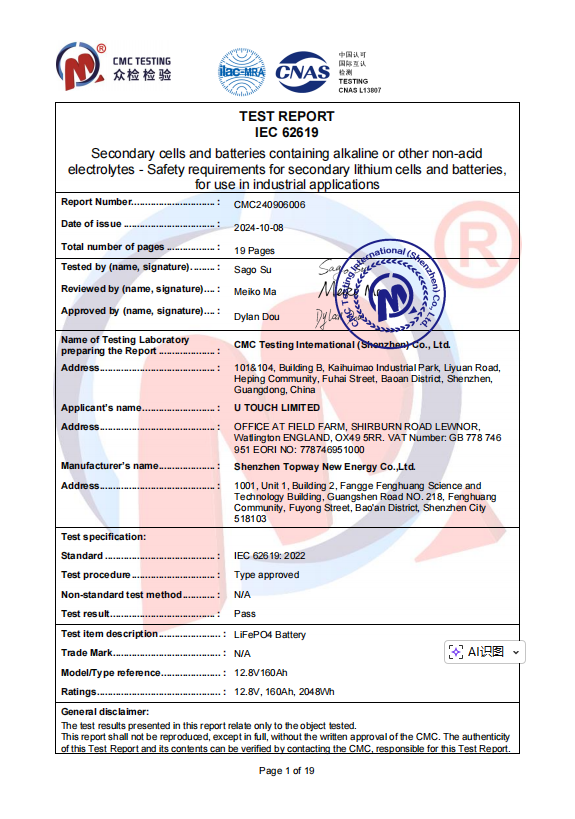

- International Certifications: Insist on batteries that have passed UL, CE, IEC 62133, IEC 62619, and RoHS. These ensure electrical, functional, and environmental safety. HCC products hold these certifications, providing a solid foundation of trust.

- Medical-Specific Standards: Depending on the device class (I, II, III), additional standards like ISO 13485 for quality management may be required. HCC's commitment to quality is underscored by its ISO 9001:2015 certification.

- Battery Management System (BMS): A robust BMS is the brain of a battery pack, preventing overcharge, over-discharge, short circuits, and ensuring cell balancing. For mission-critical robotic surgery battery packs, a redundant or highly advanced BMS is essential.

A selection of HCC's international safety and quality certifications, ensuring global compliance for your lithium ion battery needs.

Step 4: Evaluate the Manufacturer's Capability and Support

Your battery partner should be an extension of your R&D team. Here’s what to look for in a supplier like HCC:

HCC (Shenzhen Topway Technology Co., Ltd.) – Your Trusted Partner

HCC has established itself as a pioneer in medical-grade and high-performance lithium ion battery solutions. Based in Shenzhen, China, the company operates a dedicated sales and R&D center, with plans to expand into full-scale manufacturing.

Core Strengths for Medical Applications:

- Custom Design & Integration: From a single 18650 battery to complex, high-voltage battery pack systems for surgical robots or drone-based medical delivery (delivery robot battery).

- Vertical Integration Roadmap: Evolving from solution design to in-house production, allowing better control over quality, cost, and lead times for large-volume orders.

- Cross-Industry Expertise: Experience in demanding fields like racing drone battery and tactical drone battery development translates to robust, high-discharge battery solutions applicable to dynamic medical equipment.

- Global Compliance Focus: All related products pass RoHS, UL, CE and other export certifications, facilitating smooth market entry worldwide.

Contact HCC for Your Project:

Phone: +86 755 81461866

WhatsApp: +86 18682160604

Email: sales@hcctop.com

Website: http://www.hcctop.com

Address: 1001, Unit 1, Building 2, Fangge Fenghuang Science and Technology Building, Guangshen Road NO. 218, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen City.

Step 5: Prototype, Test, and Validate

Never skip rigorous testing. Work with your supplier to obtain prototype battery pack units.

- Performance Testing: Verify capacity, discharge rates, and cycle life under simulated use conditions.

- Environmental & Safety Testing: Conduct tests for vibration, shock, temperature cycling, and electrical safety.

- Regulatory Pre-Check: Use the certified battery cells and packs from a supplier like HCC to streamline your final device certification process.

Powering Innovation with Confidence

Selecting the right medical battery is a multifaceted process that balances technical specifications, safety imperatives, and supply chain reliability. By following this guide and partnering with an experienced and certified manufacturer like HCC (Topway), you can ensure your medical device is powered by a lithium ion battery solution that is safe, reliable, and performance-optimized. From smart robot battery systems for hospital logistics to the most sensitive robotic surgery battery packs, the right power choice fuels the future of healthcare.

Visit www.hcctop.com today to discuss your medical-grade battery requirements.